Our Solutions

All of our contracts begin with a GAP assessment to determine the actual needs of the client.

We find synergistic solutions to ensure you’re addressing root problems, and not the symptoms of the problems.

We use a holistic approach to determine the current state of the project and the client’s immediate needs, as well as identifying other shortfalls that should be addressed in the future.

Chemistry Manufacturing & Controls (CMC)

JPC can support your CMC needs related to your manufacturing process, quality controls, product specifications, and drug stability.

Process:

- Troubleshooting problems with the manufacturing process

- Reviewing Batch Records

- Assessing Viral Clearance for Biologics

Qualilty Control

- Evaluating & optimizing Analytical Methods

- Reviewing critical In Process Controls (IPC)

- Serving as Person in Plant (PIP) representation

Process Expertise:

- Protein Formulation

- Biologics Manufacturing

- Solid & Liquid Oral

- Dosage Forms

- Cell Therapies

- Gene Therapies

- Topicals

- Animal-derived Sterile Injectables

- Antibody Drug Conjugates

- New Chemical Entities / Small Molecules

Technical Expertise:

- Protein Chromatography

- Ultrafiltration Diafiltration (UFDF)

- HPLC

- Electrophoresis

- Potency Assays

- Virus Filtration

- Tableting

- Liquid Formulations

- …and more!

Regulatory Affairs

JPC will leverage our experience to help clients understand how Regulators will critically evaluate their submission.

- Transfers between INDs and IMPDs

- Writing support and reviews of submission documents, including Biologically Derived Materials (BLA) and New Drug Application (NDA) filings

- Ensure that the information presented to a regulator will be immediately interpretable; and adequately explained to meet the regulator’s needs

- Spheres of Experience:

- FDA

- Health Canada

- MAA submissions to EMA

Compliance & Audits

JPC can evaluate Good Manufacturing Practices (GMP)

In new engagements, we will perform an assessment of your process. We will refer to FDA regulatory guidance, ICH guidelines, and USP.

We will assemble the guidances into actionable steps to prepare your product for FDA/EMA/Health Canada.

We can also:

- Prepare your facility to go GMP

- Evaluate and implement FDA suggestions

- Design remediation and responses to 483s

JPC can help to ensure a meaningful outcome.

- Review your records, including Documentation and Training Protocols

- Prepare your team for successful engagements with FDA reps

- Review existing guidance with your team to prep questions before the meeting

Audits

- Vendor Qualification Audits

- For-cause Audits

- Prior Approval Inspection Readiness Audits

We are able to perform both on-site and virtual audits, independently, or can accompany your subject matter experts (SMEs) and compliance staff.

As an outcome of audits, JPC provides an audit report with observations and recommendations for remediation.

Executive Consulting

JPC can facilitate decision making by your executive team

- Bridging the space between the scientific team and the executive group with a Big Picture focus on risk, probability of success, and profitability

- Communicating facts, risk, and options to top level decision makers by leveraging business acumen to interpret highly technical pharmaceutical, regulatory, and manufacturing information

- Business development and support

The position of a neutral third party allows the executive team to communicate with JPC staff differently than they can communicate with internal staff members.

- Identifying all critical activities that need to be completed in sequence, and facilitating those activities with as little delay or distuption to the sequence as possible.

- Improving communication between internal stakeholders

- JPC specializes in building collaboration between departments, synergizing communications, and making sure that everyone who should be in the room is there

- Maximizing the value your company’s own existing staff to ensure the success of your project

Communicating with the Manufacturers who produce your Active Pharmaceutical Ingredients (API) and drug substance

Working with your other vendors, including third-party logistics (3PL), packagers, facilities operational support

JPC can assist with:

- Vendor Management

- Vendor Selection

- Reviewing Vendor Contracts

- Ensuring your project doesn’t get pushed to the back of the line

- Asking hard questions of your vendors to avoid group-think

Training

JPC has a proven track record of identifying gaps in personnel expertise

- Provide GMP training for your staff

- Available to work with your staff to create custom written, audio, or video trainings to improve employee skillsets or for onboarding new employees

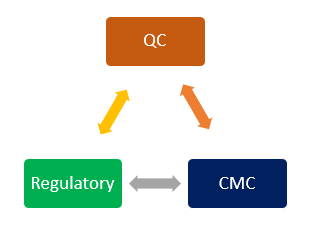

Introducing functional areas like Quality Control, Regulatory, and Manufacturing to think outside of their silos

- Get QC to care about what the Regulatory people need

- Help the Regulatory staff understand what the Manufacturing people are doing

- Teach the CMC people why the QC and Reg people need the things they’re asking for